Medical and laboratory equipment manufacturers operate in environments where reliability, cleanliness, and durability are non-negotiable. Sensitive instruments, diagnostic devices, and laboratory enclosures must withstand repeated use while maintaining precision and compliance. Bumper Specialties’ self-adhesive polyurethane bumpers are engineered to meet these exact demands.

Designed for OEM applications, Bumper Specialties’ polyurethane bumpers provide long-lasting protection, noise reduction, and vibration control for medical and laboratory equipment of all types.

Engineered Protection for Sensitive Equipment

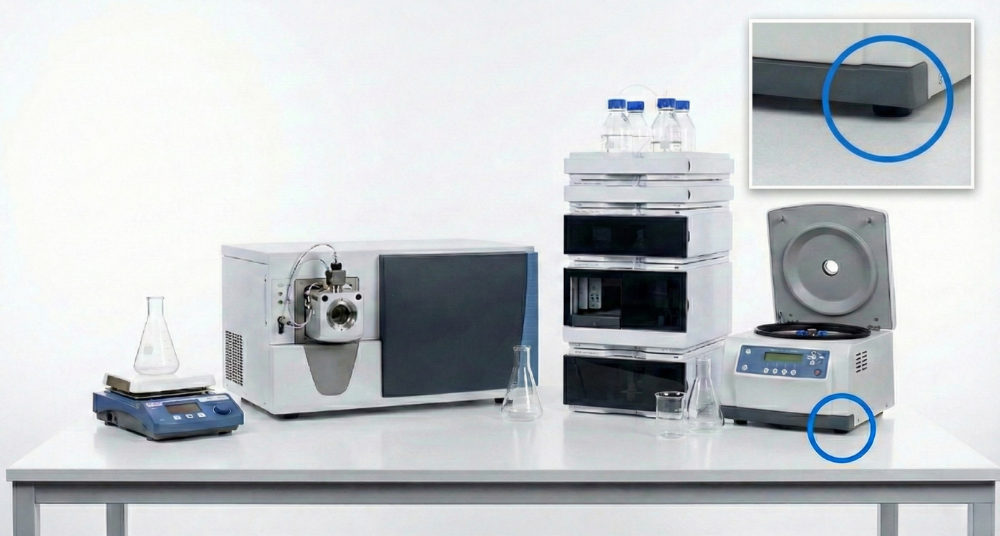

Medical and lab equipment often includes access panels, hinged doors, covers, and removable components that experience repeated contact during normal operation. Without proper cushioning, these contact points can lead to surface damage, component misalignment, or premature wear.

Our self-adhesive polyurethane bumpers act as precision-engineered shock absorbers, protecting metal, plastic, glass, and painted surfaces from impact. This added protection helps preserve equipment aesthetics, maintain alignment, and extends product life which are all critical benefits for high-value medical and laboratory devices.

Quiet, Controlled Operation

Noise and vibration control are essential in clinical and research environments. Excess vibration can interfere with sensitive measurements, while unwanted noise can disrupt patient care and laboratory workflows.

Our self-stick polyurethane bumpers are formulated to dampen vibration and reduce operational noise, helping equipment operate smoothly and quietly. When applied to panels, housings, or mounting surfaces, they minimize rattling, absorb shock, and isolate vibration at the source.

Medical-Grade Performance Characteristics

Our polyurethane bumpers are designed to deliver consistent performance in demanding environments. Key benefits include:

- Non-marring, non-abrasive contact surfaces

- Resistance to cracking, hardening, and deformation

- Excellent load-bearing and rebound characteristics

- Long-term durability under frequent cleaning and disinfection

Compared to rubber or foam alternatives, polyurethane maintains its integrity over time, making it well-suited for medical and laboratory applications.

Fast, Clean Installation for OEM Manufacturing

Our self-adhesive backing enables quick, reliable installation without tools or fasteners. This simplifies assembly processes, reduces labor costs, and eliminates the need for drilling or hardware that could introduce contamination risks.

The adhesive bonds securely to common medical equipment materials, including powder-coated metal, plastics, and glass, ensuring consistent placement and performance.

Versatile Solutions from a Trusted Manufacturer

We offer a wide range polyurethane bumpers, including multiple shapes, sizes, and durometer options. This flexibility allows medical and laboratory equipment manufacturers to select bumpers that meet exact spacing, load, and impact requirements.

Common applications include:

- Diagnostic and imaging equipment housings

- Laboratory analyzers and test instruments

- Medical carts and mobile workstations

- Equipment enclosures, panels, and access doors

- Benchtop devices and lab furniture

A Proven Component for Medical & Laboratory Equipment

For medical and laboratory equipment manufacturers, component reliability directly impacts product performance and reputation. Our self-adhesive polyurethane bumpers provide a simple, cost-effective solution for protecting equipment, reducing noise, and improving durability without compromising cleanliness or integrity.

By partnering with Bumper Specialties, OEMs gain access to high-quality polyurethane bumpers backed by application expertise, consistent manufacturing, and responsive support.